Due to the increasing worldwide nature and importance of Direct Parts Marking, UID, and Deep Engraving during the manufacturing process for traceability and production flow control, inventory control and renewal, service marks, product quality validation, long-term product liability and reliability, the United States government and the Department of Homeland Security have approved a variety of programs where lasers became an essential part of the present and future applications for Direct Parts Marking, UID (Unique Identifier), and Deep Engraving. In addition, in the private sector, various government contractors elected to use lasers to comply with strict government regulations.

The Aerospace industry represents the nation’s leading manufacturers and suppliers of civil and military components, equipment, services, and information technology. The strict government requirements and regulations drove the manufacturers involved in this complex and heavily regulated infrastructure to implement advanced, efficient, and reliable technologies capable of complementing strict standards while maintaining a cost-efficient structure.

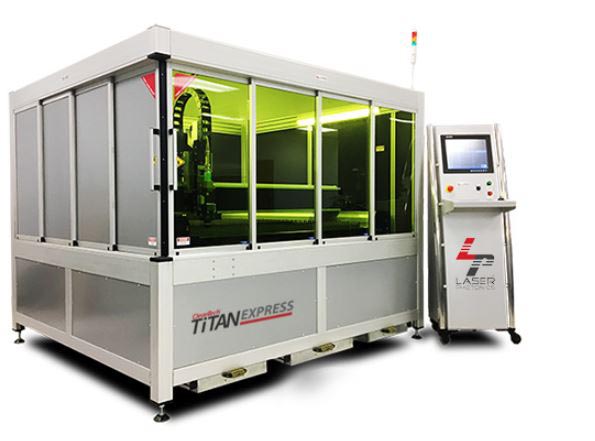

Laser Photonics technological applications for cutting, marking, scribing, quartz welding, coating ablation, and deletion were developed to match and exceed strict standards. As a result, the quality of our products surpassed exacting industry needs and was transferred to all the other markets to benefit our customers, present and future.